DDMRP Demand Driven MRP

Traditionele systemen voor materiaalplanning en -controle (ERP/MRP en systemen voor supply chain planning) zijn systemen waarin gedetailleerde prognoses worden gebruikt om de benodigde materialen en onderdelen aan te kopen. Het systeem duwt productieorders door het productie- en distributiesysteem naar het punt van verbruik. Dit systeem wordt meestal "Push and Promote" genoemd. Deze oude regels en systemen veroorzaken frictie en compromissen binnen en tussen fabrikanten in de vluchtige en complexere toeleveringsketens van vandaag.

Partners

Wij werken samen met het demand driven institute om hoogwaardige DDMRP training te leveren. Wij werken nauw samen met Wa-Systems om bedrijven te helpen DDMRP te implementeren in hun productiefaciliteiten en in hun supply chain.

Het probleem

De meeste Inkoop- en Materiaalmanagers hebben het gevoel dat ze klem zitten tussen een rots en een moeilijke plek. Tekorten aan kritieke artikelen moeten worden weggewerkt, terwijl de markt tegelijkertijd korte doorlooptijden eist, de supply chains langer worden en de beschikbaarheid van materialen niet altijd gegarandeerd is. In het huidige economische klimaat is dit urgenter dan ooit.

Helaas zijn de meeste beschikbare toolsets ontoereikend om dit conflict effectief op te lossen. In het licht van de toenemende volatiliteit en variabiliteit van vraag en aanbod. Leer over de tekortkomingen van tools zoals MRP en hoe Demand driven MRP kan helpen. DDMRP is gebaseerd op de beste eigenschappen van Six Sigma, Lean, TOC en MRP. Deze geïntegreerde maar toch intuïtieve aanpak zorgt voor lagere voorraden, een betere klantenservice, een betere benutting van de capaciteit en een lager supply chain risico.

DDMRP helpt door flow

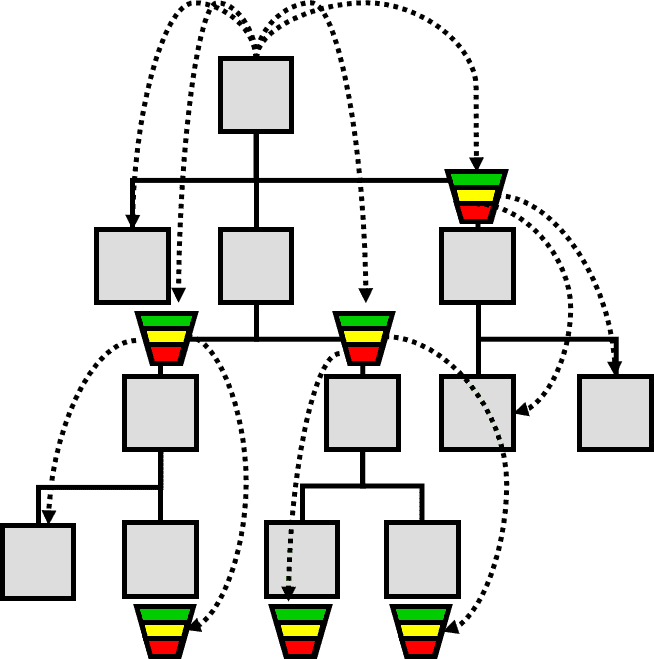

Het demand driven institute heeft DDMRP ontwikkels als een nieuwe manier om supply chains te helpen. Zij combineerden de vijf componenten van Material Requirements Planning, Six Sigma, Lean en de theorie van beperkingen om de traditionele MRP te verbeteren. De belangrijkste drijfveer van DDMRP is flow. Het concept van flow is dat, wanneer producten door een toeleveringsketen bewegen, zij waarde toevoegen. De manier om flow binnen de supply chain te bevorderen is door gebruik te maken van flow protection. Deze beschermingen zijn de zogenaamde buffers. Binnen demand driven material requirements planning help een buffer bij het tijdelijk opslaan van capaciteit om de de supply chain te beschermen tegen variatie.

Buffer

Een buffer is een vitaal onderdeel van DDMRP en is ontworpen om de bevoorradingsketen te beschermen met een pull-systeem. De innovaties van de buffer helpen bij het aanvullen en controleren van de toeleveringsketen met behulp van een pull-systeem. Omdat iedere supply chain een complex systeem is, moeten de productieonderbrekingen en de chaos die dit systeem creëert beheerst worden. Een buffer ontkoppelt de doorlooptijd en de variatie op een bepaald punt. De ontkoppeling beschermt tegen de variatie aan zowel de vraag- als de aanbodzijde. Ontkoppeling gebeurt op kritiekte punten in de supply chain waar deze nodig zijn voor de productie.

Buffers kunnen worden gebruikt om de volgende taken uit te voeren:

- Tolerantietijd klant

- Marktpotentieel Doorlooptijd

- Horizon zichtbaarheid verkooporder

- Externe variabiliteit

- Inventaris hefboomwerking en flexibiliteit

- Bescherming van kritieke operaties zoals een bottleneck

Order generation

Binnen demand driven material requirements plannng worden de leverings orders gegenereerd door de werkelijke vraag. De productie start pas wanneer er een bestelling van een klant is. Deze order wordt doorgegeven aan de volgende buffer en zo door de verschillende buffers. Voorraad buffers, gebruiken dus andere vooraad buffers om materialen te bestellen. Deze orders worden door de software gebruikt om de gewenste materialen door de toeleveringsketen en door de buffers te trekken door middel van een Pull System.

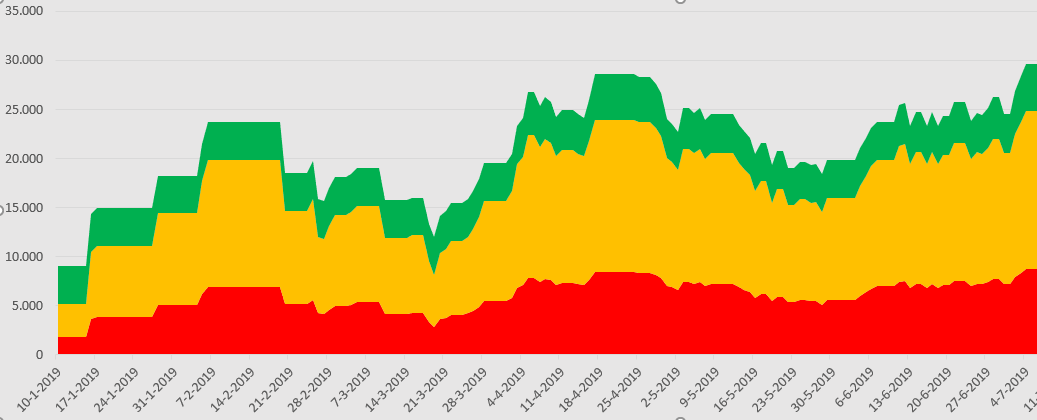

Dynamic replenishement

Wanneer de belangstelling voor een product groeit of krimpt, moet de toeleveringsketen zich daaraan aanpassen. Het Demand Driven institute kwam met de ADU, Average daily usage. Dit getal is het middelpunt van DDMRP en wordt gebruikt voor het berekenen van buffers, het bepalen van bestelhoeveelheden en het berekenen met het gewenste bestelinterval. Andere factoren die worden gebruikt zijn de betrouwbaarheid van de leverancier, de doorlooptijd en de minimum bestelhoeveelheden. Wanneer de vraag naar een product toeneemt, groeit de buffervoorraad mee, wanneer de dagelijkse vraag daalt, krimpt de buffer.

Wat kan DDMRP doen?

Bedrijven die DDMRP gebruiken voor hun planning en voorraadbeheer hebben een aantal voordelen. De meest voorkomende is minder supply chain stress. Dit betekent dat er minder verstoringen en uitzonderingen zijn. De extra tijd kan zorgt ervoor dat een planner het systeem kan verbeteren.

30-45%

Gemiddelde voorraad besparing

97-100%

Orders die op tijd en volledig zijn afgehandeld

80%

Kortere doorlooptijden

DDMRP is meer dan MRP

Wanneer een bedrijf buffers en DDMRP-logica in zijn systeem wil invoeren, is dit een vrij eenvoudig proces. Echter deze buffer inventarisatie wordt niet ingezet als onderdeel van gemeenschappelijke ERP-systemen en speciale software is nodig om DDMRP te implementeren. Wij, van Visie Partners hebben meerdere partners waarmee we samenwerken om uw vraaggestuurde materiaalbehoefte planning reis te beginnen. Meer informatie over de diensten die wij kunnen bieden, kunt u vinden op demanddriven.nl, onze eigen website gewijd aan demand driven material requirements planning.

Cursus

Om meer te leren over DDMRP en om de eenvoudige manier waarop het systeem werkt te leren, bekijk ons leeraanbod hieronder. Ervaring met DDMRP is geen vereiste, de cursussen zijn ook geschikt voor planners die in hun dagelijks werk met Demand Driven werken.

DDMRP Planner

De cursus Demand Driven Planner (DDP) is ontworpen voor professionals op het gebied van planning, inkoop en supply chain professionals die verantwoordelijk zijn voor het implementeren en handhaven van het DDMPR-concept. Dit concept legt uit op welke plekken strategische buffers geplaatst moeten worden. Dit resulteert in zo min mogelijk variatie in het productieproces en een zo constant mogelijke workflow.

DDMRP Leader

De DDL cursus is ontwikkeld voor midden en senior operations en supply chain managers die aan de slag willen met het Demand Driven Operating Model (DDOM). Onderwerpen van de cursus zijn de huidige uitdagingen voor organisaties, nieuwe managementmodellen en de Demand Driven Sales and Operations Planning