A Guide to Supply Chain Resilience: Solutions for a Resilient Chain

Why Supply Chain Resilience Matters More Than Ever

Supply chain resilience is the key to success in a world that is changing faster than ever. Today, companies rely on complex international supply chains, and disruptions are constantly looming. Think of the COVID-19 pandemic, raw material shortages, labor shortages, or geopolitical tensions. A resilient supply chain makes it possible to respond quickly, limit risks, and even gain a competitive advantage.

The past few years have shown that global supply chains can be fragile. Many companies were insufficiently prepared and struggled to keep their operations running. For supply chain leaders, the lesson is clear: investing in resilience is no longer optional; it is a necessity.

What is Supply Chain Resilience?

Supply chain resilience is about the ability of supply chains to absorb unexpected disruptions and adapt quickly. This can involve supply and demand shocks and long-term risks such as inflation, climate change, or shifting regulations. Resilient supply chains combine flexibility, visibility, and strong supplier relationships to protect processes and performance.

Example: During the COVID-19 pandemic, companies with dual sourcing and multiple suppliers were able to adapt faster. While competitors were left without critical components for weeks, they could resume production thanks to their risk management strategy. This illustrates the importance of supply chain risk management.

The Benefits of a Resilient Supply Chain

A resilient supply chain delivers tangible benefits:

- Increased visibility across the chain and faster identification of disruptions.

- Faster recovery after disruptions, reducing revenue losses.

- Stronger relationships with partners and increased trust through sharing data.

- Flexibility to handle consumer demand, even during unexpected spiked in demand.

- Competitive advantage by responding faster than the market.

- Operational excellence by aligning processes more effectively.

In addition, a resilient supply chain builds trust with customers, suppliers, and stakeholders. A company that can demonstrate preparedness for unexpected events projects reliability and stability.

Supply Chain Disruptions in Perspective

KPMG and ASCM developed a supply chain stability index that shows global volatility. They connect events such as raw materials or labor shortages to international markets and use machine learning to detect patterns. In conclusion, supply chain disruptions are increasing, and companies must invest in greater resilience and risk management to survive.

The index shows that international supply chains have become more vulnerable to disruptions. Whether it is geopolitical tensions, port congestion, or shortages of critical suppliers, the impact spreads rapidly through the entire chain. For supply chain managers, this means looking beyond their own company to supply chain partners and the broader global supply context.

The Building Blocks of Supply Chain Resilience

A resilient supply chain has several key characteristics:

- Flexibility: the ability to quickly shift production or sourcing.

- Redundancy: retaining multiple supply locations or dual sourcing.

- Visibility: supply chain visibility with real-time data.

- Collaboration: create trust and strong relationships with supply chain partners.

- Strategic risk management: supply chain risk management with clear scenarios.

- Technology: leveraging supply chain technologies such as artificial intelligence and digital twins.

By combining these building blocks, companies create chains that can better withstand disruptions and recover quickly from crises.

Three Ways to Improve Supply Chain Resilience

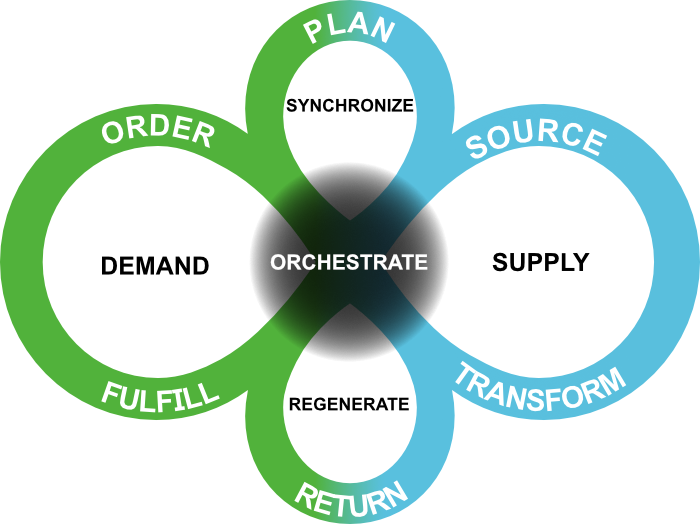

1. SCOR (Supply Chain Operations Reference Model)

The SCOR model provides a common language and framework for supply chain operations. It focuses on five key processes: plan, source, make, deliver, and return. Supply chain management can gain insights into performance and risks by benchmarking and comparing processes against best practices. This supports the development of a supply chain strategy aimed at operational excellence and risk reduction.

The SCOR model also helps companies determine their time to survive and time to recover. This allows them to better assess how long they can endure a disruption and how quickly they can resume operations.

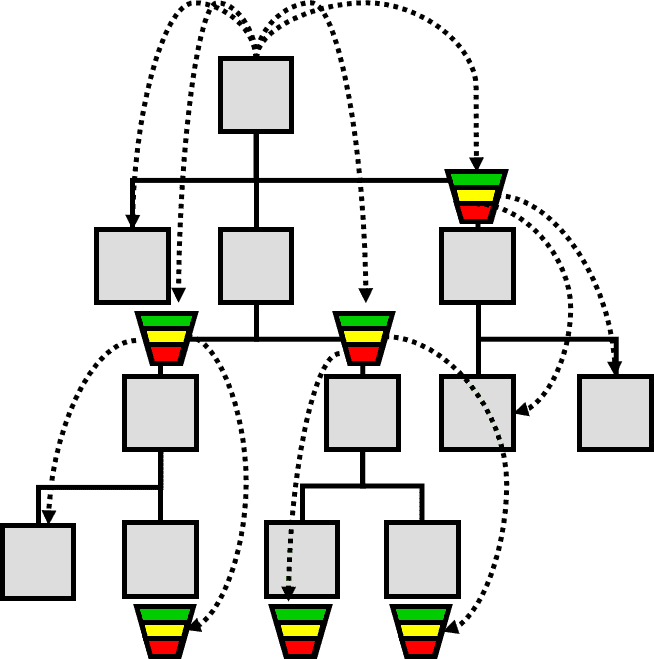

2. DDMRP (Demand Driven MRP)

DDMRP is designed to respond more effectively to fluctuations in consumer demand. Unlike traditional methods focused on forecasting, DDMRP emphasizes real-time material and information flow. Companies can better absorb disruptions by strategically placing buffers, stabilizing inventory, and shortening recovery time. DDMRP gives companies the ability to respond quickly and maintain service levels.

For many companies, DDMRP is a way to reduce uncertainties in international supply chains. It helps turn risks into opportunities by enabling faster and more flexible responses.

3. APICS CSCP (Certified Supply Chain Professional)

The APICS CSCP program equips supply chain leaders with the knowledge and tools to future-proof their supply chains. Covering the entire chain – from design and planning to execution, delivery, and continuous improvement – the program prepares professionals to lead with confidence. Students learn to use risk management, supplier contracts, and supply chain technologies (artificial intelligence and digital twins) to increase resilience. For professionals aiming to accelerate their careers and strengthen their organizations, CSCP is a high-return investment.

Technology as a Driver of Chain Resilience

The role of technology in supply chain resiliency is growing rapidly. Artificial intelligence helps forecast demand spikes, while digital twins allow companies to virtually simulate their entire supply chain. This enables analysis of specific risks, scenario testing, and better anticipation. Supply chain technologies allow companies to respond faster and align processes more effectively.

E-commerce and data sharing also bring new challenges and opportunities. Companies that leverage supply chain technologies intelligently create greater visibility and build greater resilience.

Risk Management and Strategy

Risk management is at the core of supply chain resilience. It’s not just about identifying risks but also about developing strategies to address them. Examples include supplier contracts with clear terms or spreading production across facitilies.

A strong supply chain strategy includes:

- Analysis of specific risks in the chain.

- Alignment with supply chain partners on possible responses.

- Use of data and technology to respond quickly.

- Long-term focus: building resilience is an ongoing process, not a one-time project.

Supply Chain Resilience in Practice

Building a resilient supply chain requires more than frameworks. It requires:

- Diversification: multiple supply locations and dual sourcing to reduce dependencies.

- Technology: leveraging advanced technologies, digital twins, and artificial intelligence for simulation.

- Collaboration: creating trust and strong relationships with supply chain partners.

- Strategy: a supply chain risk management plan considering time to survive and time to recover.

Companies that combine these elements build greater resilience and can survive unexpected disruptions and emerge stronger.

Extra Insight: Greater Resilience in Practice

Companies that take supply chain resilience seriously notice clear advantages. By embedding resilience into their supply chain strategy, they can quickly adapt to market trends, emerging risks, and unexpected events. This proactive approach not only helps to prevent disruptions but also builds greater resilience over time. Organizations gain the ability to create greater visibility across their global supply network and provide insights that improve collaboration with partners. As a result, resilient companies recover faster, operate with more stability, and can seize opportunities in the medium term when competitors are still struggling.

Balancing Capacity and Flexibility

Another important aspect of resilience is how companies manage their capacity. Running at full capacity might look efficient on paper, but it increases exposure to supply chain risks. When unexpected supply chain disruptions occur, companies operating without spare capacity often cannot adjust production or services quickly. Resilient supply chains deliberately leave room for flexibility, ensuring they can redirect resources, adjust operations, or shift services when disruptions or sudden changes in consumer demand appear. By not overcommitting their capacity, resilient supply chains maintain the ability to handle both short-term shocks and longer-term challenges. This approach transforms supply chain risks into manageable scenarios, reducing the chance that a single supply chain disruption causes widespread operational breakdowns.

Companies that take supply chain resilience seriously notice clear advantages. By embedding resilience into their supply chain strategy, they can quickly adapt to market trends, emerging risks, and unexpected events. This proactive approach not only helps to prevent disruptions but also builds greater resilience over time. Organizations gain the ability to create greater visibility across their global supply network and provide insights that improve collaboration with partners. As a result, resilient companies recover faster, operate with more stability, and can seize opportunities in the medium term when competitors are still struggling.

Conclusion

Supply chain resilience is no longer a luxury but a necessity. Companies that invest in visibility, technology, and collaboration are better positioned to respond quickly and recover quickly from shocks. Whether it is inflation, e-commerce, safety regulations, or geopolitical risks, a resilient supply chain protects processes and people. With models like SCOR, methods like DDMRP, and programs like APICS CSCP, companies have the tools to make their supply chains future-proof.

Want to learn how to make your supply chain more resilient?

At Visie Partners, we help professionals with programs such as APICS CSCP and DDMRP training. Contact us and discover how to strengthen your organization in an uncertain world.

Get in touch about A Guide to Supply Chain Resilience: Solutions for a Resilient Chain